-40%

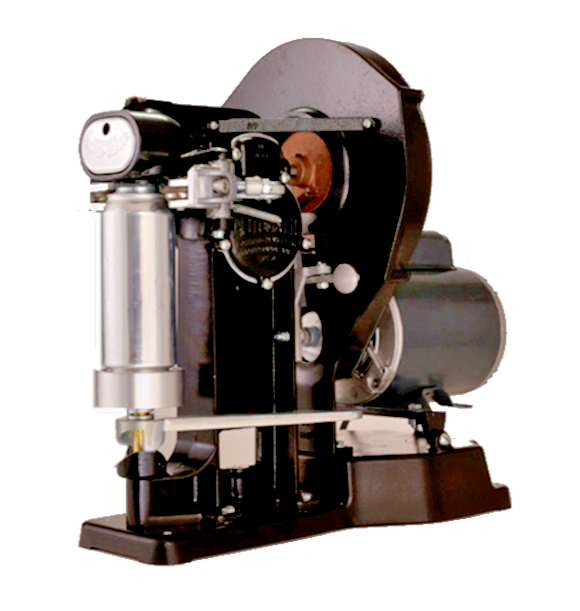

All American Electric Beer Can Seamer Sealer Canner for 12 & 16 oz Cans ELS202A

$ 924

- Description

- Size Guide

Description

An amazing new innovation in Homebrewing!Seal your own 12 oz or 16 oz beer cans right at home like the pros. Fill them with homebrew or your favorite beverage, then set the can onto the stage and turn on to perfectly seal in about 5 seconds.

This listing is for the Electric version (pictures one through 4). We also sell the flywheel version which is easy and smoothe to crank. We also sell the version with just a one handle Crank for even less. Check out our other listings.

Cans are recyclable, can be taken on the river, to the beach, camping, hiking and are much more versatile than glass. Canned beer lasts years longer than glass. Not to mention having your own canned beer is incredibly cool!

We are super excited to have these in our lineup. Please don't hesitate to send us a message if you have any questions.

We also carry the 12 and 16 oz cans for your next batch. Cans can also be purchase at many online retailers.

Labels are really fun to make and order from grogtag or even make your own with an Avery label sticker right in your own printer at home.

Homebrew clubs, microbreweries and homebrew shops love having "canning night." Join the fun with canned beer that's delicious to crack open, give away as gifts or save for a rainy day!

From the Manufacturer

This can sealer was thoroughly inspected and tested at the factory before shipment. I

The ELS202 comes with a special 202A Chuck and the D203 Base Plate. These are designed and set up to seal a 12 or 16 oz can. A sample can was used to set up the machine and was locked in place during shipping to help protect the machine. NOTE: The cans supplied by Wisconsin Aluminum Foundry Co. are only good for filling with beer.

Prior to removing the container, lower and raise the base plate by turning the Can Lifter Handle as far as possible to the left and then back to the right a few times. Pay attention to the amount of pressure you have to apply to the Lifter Handle when locking the can into place. It is good to develop a feel for the amount of base plate pressure required to properly seal a can. Cans with a bigger or smaller diameter will require a different size Chuck and Base Plate. Height adjustment with spacers is necessary before attempting to seal other size cans.

GETTING STARTED

1. The first thing to remember is to never operate the machine without a can locked in place between the base plate and chuck. If you run the rollers against the chuck it will eventually cause damage to the rollers and they will need to be replaced.

2. The sealer can be firmly attached to a table or bar using the four bolt holes (cast into sealer base) to bolt down the sealer. If that isn’t possible, you can use a C-clamp to attach the sealer to a bench top.

3. To seal 12 or 16 oz cans the seaming lever rivets (CY-22R) should be in the “S” hole of the cam roller arms (CY-22). (They come in the number 3 hole for shipping.)

4. Lower the Base Plate (CY-3) by turning the Can Lifter Handle (CY-10) as far as possible to the left.

5. Place lid on filled can and set can on Base Plate (CY-3).

6. Raise can until it is clamped firmly between the Base Plate and Chuck by turning Can Lifter Handle (CY-10) as far as possible to the right until handle locks itself against the Frame (CY1X). The can is now ready to be sealed.

7. Plug in the can sealer to 120 volt power source. Once plugged in turn the canner on and keep running until the first operation roller pulls away from the can. This hooks the lid to the can. Keep the can turning until the second operation roller touches the can; continue running until the second operation pulls away from the can. This finishes the seal.

8. When both arms are away from the can, pull can lifter handle toward you and remove can.

9. Wipe down the machine frequently to prevent buildup of foreign material.

10. The motor is built to run continuously and it is better to leave it on. If the sealer isn’t going to be used for a couple of hours or more, it is better to turn the switch off.

ALL AMERICAN

AUTOMATIC MASTER CAN SEALER

LIMITED WARRANTY

This quality Automatic Master Can Sealer is designed and manufactured to provide many years of satisfactory performance under normal use. Wisconsin Aluminum Foundry guarantees to the original owner that should there be any defects in material or workmanship during the first ninety (90) days after purchase, we will repair or replace it, at our option. This warranty does not apply to damage caused by shipping. To obtain service under the warranty, please do the following:

Return transportation will be prepaid on all can sealers under warranty. Repairs made after the warranty has expired will be billed at the current repair costs.

We want you to obtain maximum enjoyment from using this quality can sealer and we ask that you take the time to read and follow the operating instructions. Failure to follow instructions, damage caused by improper replacement parts, abuse, or misuse will void this warranty.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state. This is Wisconsin Aluminum Foundry’s guarantee to you and is being made in place of all other express warranties.